Weaving

Cutting-edge weaving machinery and advanced technologies, we take pride in consistently delivering top-quality textile terry for over decades. This includes

1 Warping Machine (German Benninger) 8500kg / Day

1 Warping Machine (Pakistan Brand) 8500kg / Day

1 Sizing Machine (German Benninger) 17000kg / Day

32 Machines (Toyota Air jet JAT 810) 10400kg / Day

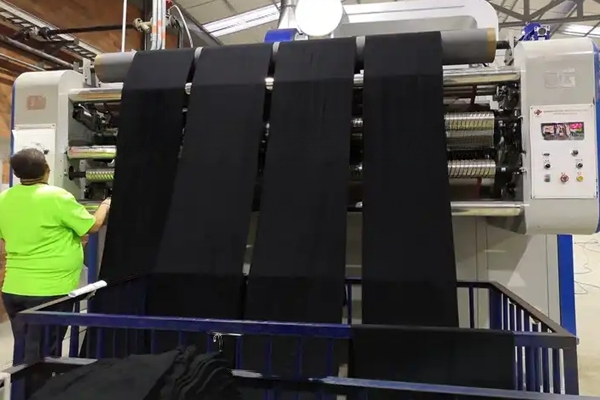

Dyeing

At Lal Industry, we believe that the art of dyeing is as crucial as the fabric itself. Our meticulous approach to selecting and utilizing dyes and chemicals ensures that each product is a masterpiece, reflecting the essence of our brand. Explore the world of Lal Industry, where color meets craftsmanship. Our commitment to excellence is reflected in our careful selection of dyes and chemicals, ensuring a spectrum of stunning hues and premium fabric finishes.

Cone Dyeing

Discover the artistry of color perfection with Lal Industry's Cone Dyeing. Our specialized cone dyeing process is a testament to our dedication to precision and vibrancy in textile manufacturing with a Per Day capacity of 2000 kgs.

Towel Dyeing

Our specialized towel dyeing process is designed to elevate your everyday essentials, ensuring a perfect blend of color, softness, and durability. Our Machinery includes

1 Machine 1600 Kgs, Machine 1200 Kgs, Machine 800 Kgs

Per Day Capacity 14,000 Kgs

Soft flow Machines, 2 Machines of 1000 Kgs

Conveyor Dryer- 1 (Model 2015) Per Day capacity: 9000Kgs

Pentek Dryer- Per Day Capacity 10,000 Kgs

CMT

We possess state-of-the-art cutting and sewing machines, ensuring efficient and rapid production. Supported by auto slating machines (2), Long Hemming Machines (2 KINDAI co Ltd) (1 –T- PET), and Auto Trimmer Machines Bando, our automated conveyor belt system ensures a seamless Cut to Pack supply chain.

Warehouse

Our warehouse is strategically designed to optimize efficiency in handling and storing our diverse range of textile products. With a meticulous layout and advanced inventory management systems, we ensure a seamless flow in our supply chain with a capacity of 24 x 40ft containers at a time. We also hold the capacity to hold the grey stock to ship as per clients' schedules.